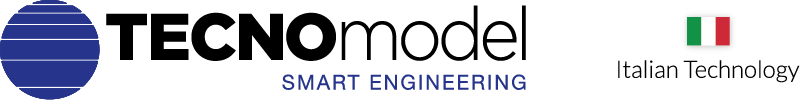

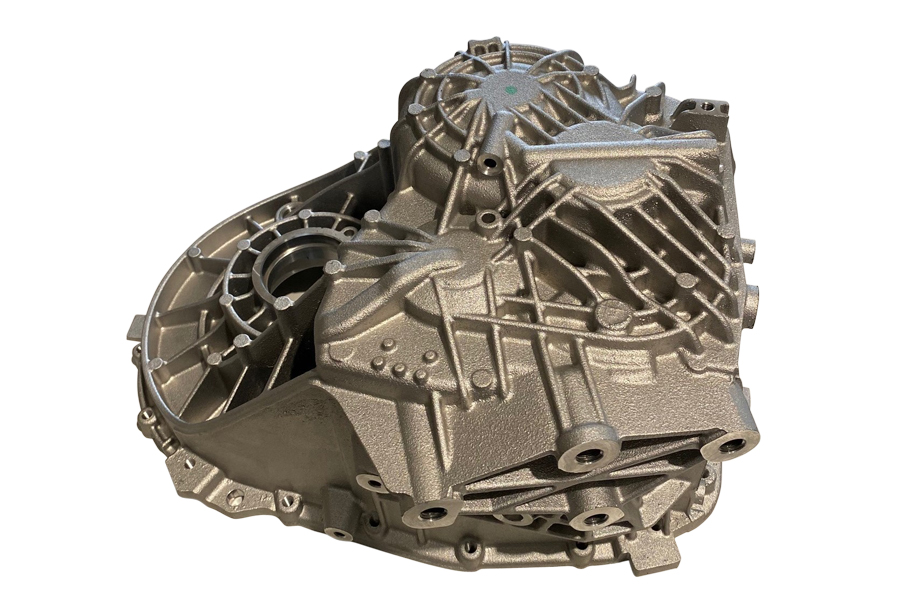

Prototypes and small series complete with mechanical machining

The prototype is the original model or the first piece of an artifact, compared to a sequence of equal or similar subsequent construction. It is normally realized in a handicraft way and scaled 1:1; testing, changes and improvements to the final product should be done on the prototype in order to to use it for the series production. The prototype can be conceptual, functional, technical or for pre-series and in any event it can serve a lot of functions inside the company: it can be used to evaluate the costs, the cycles time, business answers and so on.Use of prototypes:

- It makes a decision project more explicit, this allows designers to give correct information since the initial project.

- It allows designers to explore a lot of design concepts before taking a final decision.

- It allows to embed the feedback received from the user into the project, from the earliest stages of the production cycle.

- It allows to analyse many variants of the project and to make alternative projects.

- Improve the quality and completeness of project specifications.

The prototypes could be realized from cast or full CNC; in aluminium, cast iron or steel.

The production of the prototype and small series involves the following steps

- To check customer's ideas and targets

- The feasibility study

- Product design

- The equipment production

- The prototype construction

- The small and medium series production

Rapid prototyping (RP)

It allows to realize the prototype, in short time, by a 3d drawing model of the product.We manage:

- Fused Deposition Modelling ( FDM- ABS Plus).

- Selective sintering (SLS).

- Silicon soft tooling.

- Sand resin foundry mould.

Traditional prototyping

- Prototype realized from full CNC ( CAD-CAM processing)

Material: aluminium, cast iron and sheet - Prototype realized from sand casting with CNC machining & full treatment

Material: aluminium, cast iron and sheet - Prototype realized from investment casting with CNC machining

Material: steel